Feature on HONYAKI Japanese kitchen knives

Honyaki knives are forged solely from one material: high-carbon steel (called “Hagane”). The structure method used to make Honyaki knives is similar to that used to make traditional Japanese swords, which is a very difficult and long process.

After being heat treated, the blade is hammered repeatedly to form the shape of a blade and evenly distribute the carbon and chromium molecules. It requires the precise techniques of skilled and experienced craftsmen.

Check all items of Honyaki Knives >

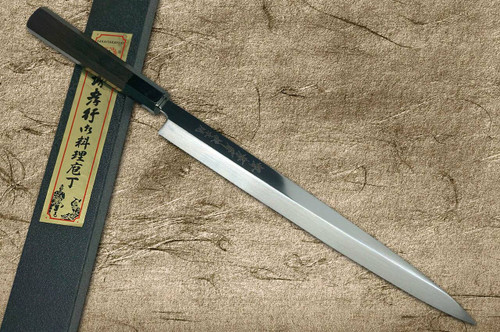

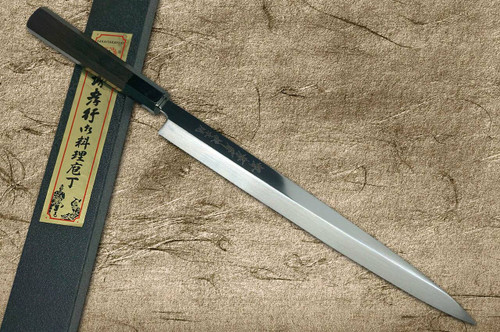

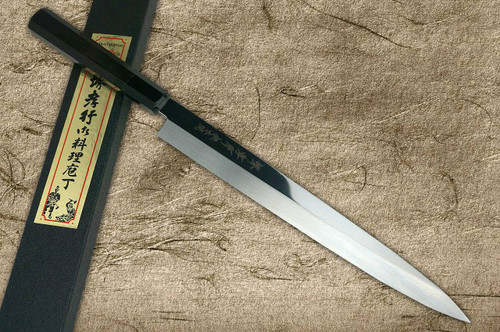

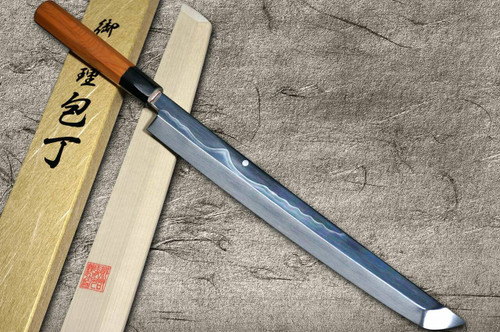

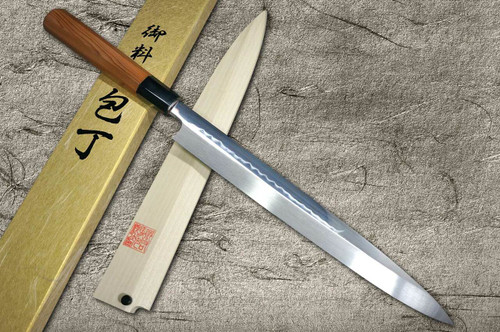

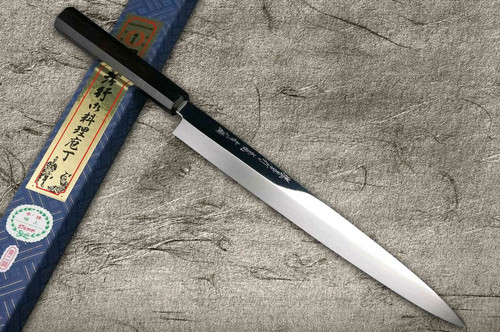

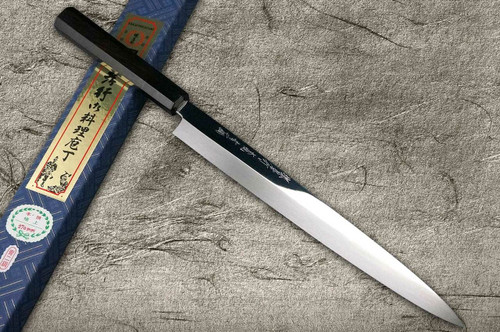

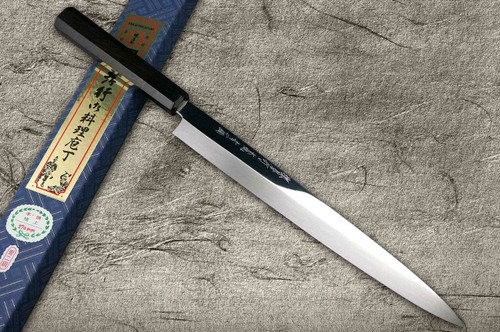

Recommended Honyaki Knifes

* There are additional items other than the above. Search by the keyword "HONYAKI" to find the best knife >> Search Engine

* You can order some customized left-handed knives if you allow a longer lead time and cost.

When you need more information and want to order the one, please do not hesitate to contact us. We'll support you as much as possible.

Why Were Honyaki Knives Developed?

Let’s illustrate the differences between Western knives and Japanese knives with a cross-sectional diagram. Figure 1 shows the cross-section of a standard knife. The left shows a Western (Gyuto) knife that is made entirely with carbon steel or martentistic stainless steel. The four on the left are Japanese knives, of which 3 are composite.

Only Western-style kitchen knives generally made in Western countries and Honyaki knives in Japan are made of entirely of a single material like a carbon steel or a high carbon stainless steel (which we call all-steel, or all stainless), while most of Japanese kitchen knives (other than Honyaki) are often composite knives. This composite structure is ideal for knives that will be sharpened on a whetstone.

Even if a knife has a composite structure, there is a specific problem which does not occur with a Warikomi and San-Mai Awase both of which are double-edged knives. This problem occurs with only thin & long sashimi knives, Yanagiba and Takohiki, and thin & wide Usuba knives, all of which have single-edged thin blade.

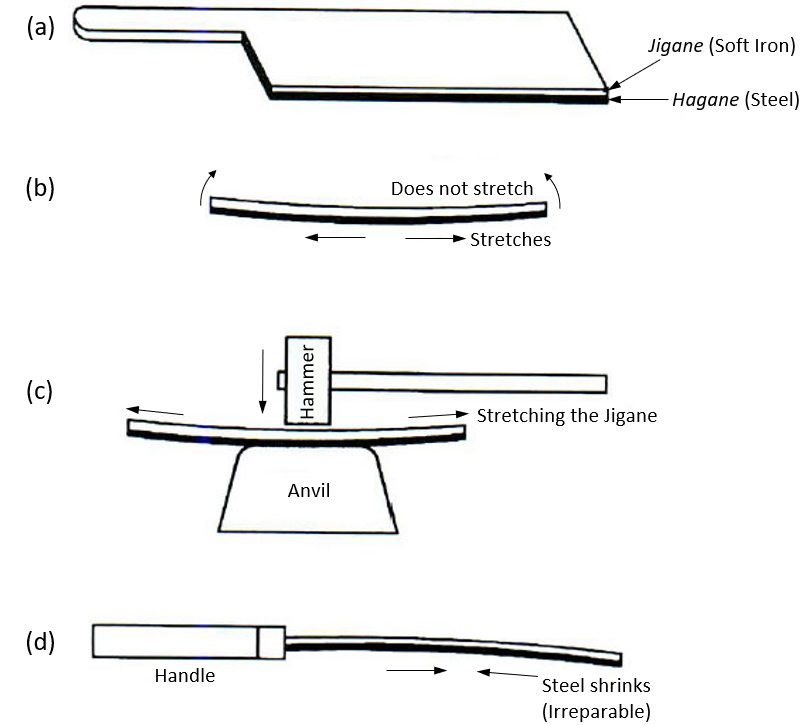

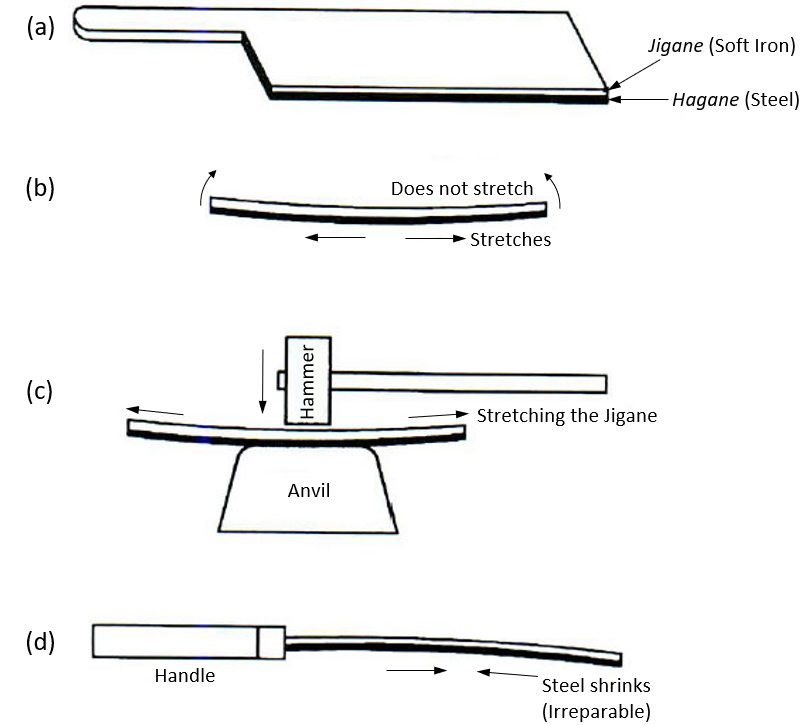

Fig.1 Why Thin-Bladed Composite Usuba Knives Warp

Figure 1(a) is a concept drawing of a Usuba knife that has been coated with steel, the upper white portion is Jigane, while the black portion on the bottom is steel. By heat treating this, the steel becomes martensitized, increasing in length as it cures. The white portion, composed of Ferrite, remains soft. Thus, as in Figure (b), it’s typical for the knives to warp upwards when viewed horizontally. In order to correct this, the knife is placed on an anvil as in Figure (c), where the steel is placed downwards and the Jigane is struck with a hammer, extending it and straightening the knife.

Only Western-style kitchen knives generally made in Western countries and Honyaki knives in Japan are made of entirely of a single material like a carbon steel or a high carbon stainless steel (which we call all-steel, or all stainless), while most of Japanese kitchen knives (other than Honyaki) are often composite knives. This composite structure is ideal for knives that will be sharpened on a whetstone.

Even if a knife has a composite structure, there is a specific problem which does not occur with a Warikomi and San-Mai Awase both of which are double-edged knives. This problem occurs with only thin & long sashimi knives, Yanagiba and Takohiki, and thin & wide Usuba knives, all of which have single-edged thin blade.

After the product is ready, but as time passes after production the steel side shrinks as Figure (d), warping in the opposite direction as shown in Figure (b). Heat-treated steel cannot be lengthened and there is no way to straighten out and fix the knife.

Whether or not the Forging process that starts the mounting of steel is done carefully, is said to greatly affect the deformation of the product. Fundamentally, the reason behind this warping is the pasting of two materials, a soft material in Jigane and a hard material in steel. This being the case, the solution would be to make a knife out of a single piece of metal, which was the Honyaki.

According to A History of the Sakai Cutlery Manufacturer’s Association, published by the Sakai Cutlery Manufacturer’s Association in March of 1978, the distinctive feature of a Sakai knife is in the combining of jigane and hagane. Starting with single-edged, layered knives, swordsmiths of the early Meiji era who during sword prohibition found themselves unable to forge swords, began to use their techniques to forge knives, hoping to fix the shortcomings of these knives and starting the creation of the Honyaki knife. Though not described in detail, the single-edged layered knife was created first, and in order to prevent the irreparable warping of hagane as shown in Figure (d) caused by the long-term use of the knife, an all-steel knife that would not face this same problem was likely created with swordsmithing techniques.

In this author’s opinion, the value in a Japanese sword is in the combination of both hardness and toughness that is created by combining hard steel with a soft core, and that the name “Honyaki” likely derives from quenching of a fully method of the all-steel blade where the clay applied on the blade is thinned only on the edge, signifying that the method of quenching was “similar to that of a Japanese sword”.

The sugu-ha, gu-nome, midare, and various other forms of hamon, the wave-like patterns seen on the surface of the blade, can be said to be the greatest attraction of a Japanese sword, but in the case of knives, as the polishing of the blade is not as intricate, the burnished edges do not appear as clearly as the hamon (yakiba) of Japanese swords you would see at a museum or the like.

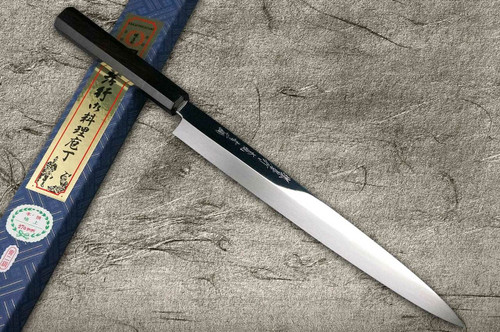

Today, however, it is not uncommon to find Honyaki knives that have undergone such intricate polising to produce beautiful hamon on the blade. The picture above is one of the Honyaki with beautiful Mt.Fuji and wave patterns.

[Referenced from Hamonoarekore by Kato and Asakura(2013)]